We offer various equipment.

Wafer Mounter

(300mm Fully-Automatic Remounter)

(300mm Fully-Automatic Remounter)

-

1.Remounting process performed on one table

After cutting the tape that is mounted on the wafer, a new dicing tape is laminated onto the opposite side of the wafer; this entire process is performed on one table (transfer mount). Because the entire remounting process is performed on one table without releasing the adsorption, the risk of wafer cracking decreases allowing for the processability of thin wafers (≥30µm).

-

2.Tape cutting performed by a 6-axis robot

Cutting radius, speed, depth, angle, and heater (up to 90℃) are all freely adjustable allowing for optimal tape cutting.

-

3.Multiple different methods of remounting available

Standard: 12inch ring frame→12inch ring frame

Options: 8inch ring frame→8inch ring frame, 8 inch ring frame→12inch ring frame -

4.Double load ports are standard

Different load ports can be used when loading/unloading a workpiece.

Options

- Host Communication Function

(Communication Format:Conforms to SECS-I and HSMS/

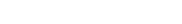

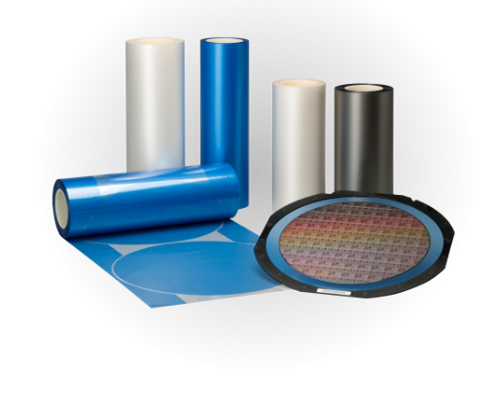

Software:Conforms to GEM) - Dicing Tape

In-Line Pre-Cutting - Vision System

(Wafer ID Reader & Barcode Attachment System)