We offer various equipment.

Wafer Mounter

(300mm Fully-Automatic Multifunction Wafer Mounter)

(300mm Fully-Automatic Multifunction Wafer Mounter)

-

1.Compatible with ultra-thin wafer

This is a stand-alone system, and the ideal wafer multi-mounting system for ultra-thin wafer manufacture. From UV irradiation following the back grinding process, to alignment, mounting on dicing frames, and peeling of back grinding tape, all in a single machine.

-

2.Wafer handling cycles minimized

The handling frequency of wafer is reduced to four times in stand-alone, and reduced to two times in in-line system. As a result, the damage to wafer is suppressed to the utmost limit.

-

3.High throughput

High throughput is achieved by optimizing the transfer component.

*There is an increase in throughput of approximately 60% relative to general equipment (Throughput compared by the operation of 300mm bare wafer. Actual throughput varies with lamination and peeling conditions). -

4.Reduced footprint

It has an extremely compact design, which measures 2,165mm(W) x 3,090mm(D) x 1,800mm(H) (not including the signal tower and protruding parts).

*Compact design reduces equipment footprint by approximately 30% relative to general equipment. -

5.Dicing tape with in-line pre-cut system (optional)

Even if non pre-cut dicing tape is used, the optionally installed tape cutting mechanism with an unique in-line pre-cut system will not damage the ring frame as the tape cutting is conducted inside the equipment.

-

6.Heat seal/adhesion peeling tape lamination

For back grinding tape removal, both heat seal method and adhesive tape method (optional) can be used together in accordance with the physical properties of the back grinding tape used.

-

7.Supports DBG™ process (optional)

In addition to regular ring frame mounting with 300mm/200mm wafers and removing of back grinding tape, this mounter supports the DBG™ (Dicing Before Grinding) process, which is ideal for thin die fabrication.

-

8.In-line compatible with DISCO Corporation's DFG8000 series or DGP8000 series (optional)

By combining this mounter with the DISCO Corporation's DFG8000 series back grinder or DGP8000 series grinder/polisher, an in-line system with work space-capable of drastically reducing the risk of damage during the handling of thin wafers can be structured.

Options

- Host communication function

communication format: conforms to SECS-I and HSMS/Software: conforms to GEM - Vision system

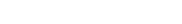

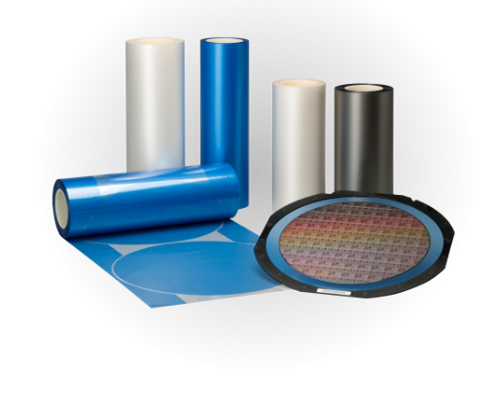

- Dicing tape

in-line pre-cutting - DBG™ process compatibility

- In-line operation with DISCO Corporation

DFG8000 series or DGP8000 series