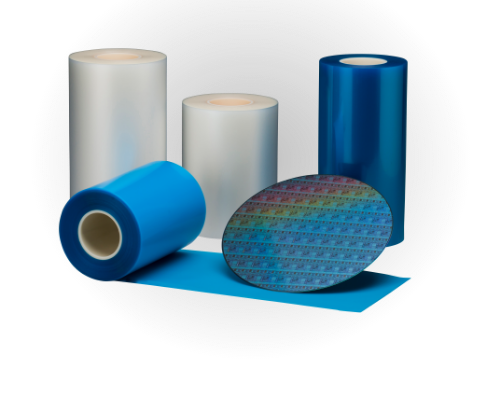

We have now improved the performance of the top-selling model “RAD-3510F/12” and have developed the “RAD-3520F/12,” which offers better performance and a smaller footprint.

- 1. Double load ports are standard

- 2. FOUP opener with wafer mapping function is available as standard feature

- 3. Approximately 30% smaller footprint compared to conventional models

- 4. Achieves a high productivity of 70 wafers/hour

Additionally achieves a maximum of 100 wafers/hour with the high speed spec option. - 5. Improves wafer processing volume per roll of tape a maximum of 16%

*When the tape is a 100m roll and the wafer size is 300 mm (12 inch) in diameter - 6. A wide variety of optional functions are installable

ESD countermeasures, various cleaning functions, automatic cutter exchange etc. - 7. CE/KC marking, SEMI S2/S8 compliant