-

1.Compact and high-throughput

This equipment handles wafers of both 300mm and 200mm. More compact with an integrated cassette loader and unloader. Provides high-throughput with two processing lines.

-

2.High quality and high performance

This is a sophisticated system developed by Lintec, the industry-leading supplier of UV curable dicing tapes. Supports the optimization of illuminance and light intensity with high output UV lamp and light intensity checking for each wafer process, and performs UV irradiation in an environment that prevents inhibition by oxygen*.

*Conducts UV irradiation in a chamber filled with nitrogen to expel oxygen which inhibits UV curing. -

3.Smooth and safe operation

A large touch panel improves operability. Ensures safety for operations and maintenance, complying with the SEMI safety guidelines, from design to assembly stages.

Supports CE marking -

4.Factory automation of assembly process

It realizes factory automation of total assembly process by integrating host communication function and inline system.

We offer various equipment.

UV Irradiation System

(300mm Fully-Automatic UV Irradiation System)

(300mm Fully-Automatic UV Irradiation System)

Options

- Host communication function

communication format: conforms to SECS-I and HSMS/Software: conforms to GEM - Barcode reader for selecting recipes

- Barcode reader for

reading ring frame ID - Double loader/unloader

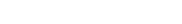

Suitable Tapes

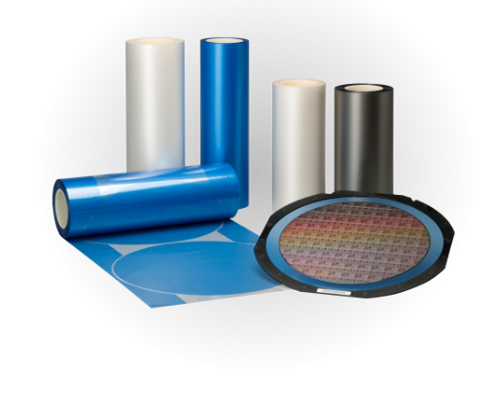

Operation Process

-

A.Workpiece Loading, Scanning, and Unloading

A workpiece is automatically detected in the cassette, and then passed to the alignment unit.

-

B.Irradiation Preparation

The workpiece is aligned, placed onto the lower pass line of the transfer arm, and then transferred to the UV irradiation starting position. The chamber is filled with nitrogen at this time.

-

C.UV Irradiation

The workpiece in the chamber is moved above the UV lamp to be uniformly irradiated.

-

D.Storage Preparation

The UV-irradiated workpiece is transferred along the upper pass line of the chamber and transfer arm, and then waits for being unloaded in the upper alignment position.

-

E.Workpiece Storage

After the next workpiece is loaded into the chamber, the processed workpiece is stored in the cassette.